Welcome to Gemini Marine Products

Our stainless does what others just can’t

Our 316 stainless steel fittings, including our exclusive, patented hinges and struts, set new standards in marine canvas hardware. Tried and trusted on hundreds of boats, they offer you a wide new range of possibilities.

Designed to be flexible and adaptable, now you can have a folding dodger frame with better cockpit access, solar panels on your bimini top mounted on hidden structures and a host of accessories on pretty much any tubing.

You can shop our full range and buy securely right here. We’ll help you love your boat even more.

*NEW* product:

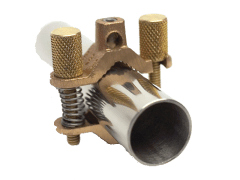

DrillSteady PRO

DrillSteady PRO is a tough bronze version of our 5-star drill guide.

We’re so sure it will keep up with you that it comes with a lifetime guarantee.

Read more and buy today.

There’s a kit for that

Looking to add grab rails or upgrade to a

strapless bimini?

Our kits are just the ticket.

All the hardware you need included.

Choose your grab rail kit now.

Choose your strapless bimini kit now.

SALE

A foundational piece in so many ways, flat-based deck hinges are always in demand.

To help put them in your hands for your Winter projects, our 90 degree and angled deck hinges are now

only $7 each.

Buy yours here.

Oops?

Lost a little something?

Check out our expanded selection of hardware,

nuts, bolts and screws to get your job back on track.

You’re welcome.

2023 Award of Excellence

We did it again.

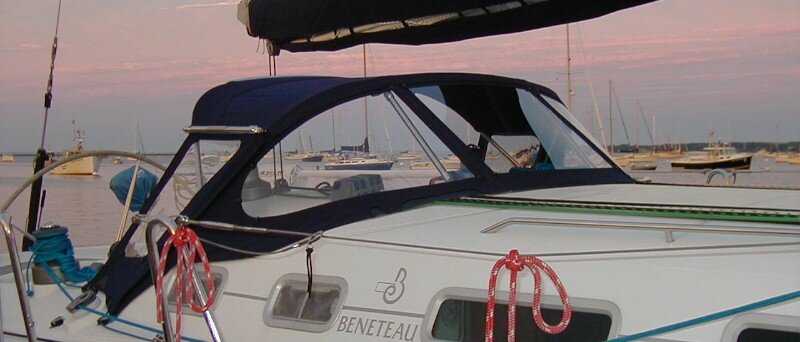

Our client wanted a full enclosure and matching sail cover with rigid solar panels that didn’t interfere with the boom (and vice versa – solar panels don’t like shade). It took a bit of doing, but John created a frame that gets the panels up and over the boom. It uses our own split side mounts to secure the panels, as well as a host of other hardware and fittings. The canvas looks great, the panels work great, the client is pleased as punch. Problem solved.

The build just won an Award of Excellence from the Advanced Textiles Association Marine Fabricator division. It was featured in the March edition of Marine Fabricator magazine. We couldn’t be happier.

Not all solar builds are this complex, but if we can do this, we can get solar on your boat, too. Give us a call.

Celebrating 30 years of excellence

John won his first design award from the Advanced Textiles Association (ATA)

in 1997 and was named a Master Fabric Craftsman by the

ATA’s Marine Fabricators Association in 1999.

Don’t take our word for it

Our reviewers say it better

5 star products

“Great product. Well made and a credit to my yacht.”

5 star service

“Wow! This is a company you will want to deal with.”

5 star for DIY

“This is my second purchase…these will allow me to fab vs hiring a welder.

Saving some bucks, yet with a quality installation.”

Looking for Gemini Marine Canvas?

For an introduction to our bespoke canvas work, please visit our sister site here

or contact us for more information.